leeb hardness testing method|units for rockwell hardness test : exporters Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). Por ello, la calificación de autoclaves es un proceso crucial para verificar su rendimiento y conformidad con los estándares de calidad, a continuación, se relacionan los puntos clave a considerar durante la calificación de autoclaves.

{plog:ftitle_list}

With that foundation, let’s take a look at some material make-up of low-density polyethylene (LDPE) and high-density polyethylene (HDPE). Both of these types of plastic are commonly used to make plastic containers and bins that are .

Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg.

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).

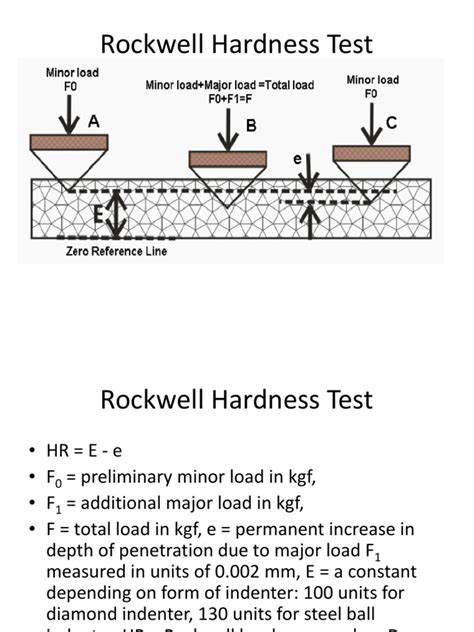

units for rockwell hardness test

3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). 1.2 The values stated in inch-pound units are to be regarded as the standard.The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications.ISO 16859-1:2015 covers the determination of a dynamic hardness of metallic materials using seven different Leeb scales (HLD, HLS, HLE, HLDL, HLD+15, HLC, HLG).

Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.ISO 16859 consists of the following parts, under the general title Metallic materials — Leeb hardness test: — Part 1: Test method. — Part 2: Verification and calibration of the testing devices. — Part 3: Calibration of reference test blocks.

Scope. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).The Leeb hardness testing, otherwise called as Leeb Rebound Hardness Test (LRHT), is considered as one of the four commonly used methods to test the hardness of the metal. It is a type of non-destructive testing used to inspect large sized workpieces weighing above 1 kg.The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg).

3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). 1.2 The values stated in inch-pound units are to be regarded as the standard.

The Leeb hardness testing method uses a conical indenter and ball indenter to measure the hardness of a material. This article explains how this method works and its applications.ISO 16859-1:2015 covers the determination of a dynamic hardness of metallic materials using seven different Leeb scales (HLD, HLS, HLE, HLDL, HLD+15, HLC, HLG). Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .

Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness.

types of rockwell hardness test

does speed clean autoclave cleaner expire

portable leeb hardness tester

Autoclave presents easy equipment accessibility, lower cost consumables, higher reduction of remaining pulp and complete sterilization, reason why was considered the most .Sterilization of disposable face masks by means of standardized steam sterilization at 121°C could be an alternative during face mask shortages due to COVID-19 as long as the fit does not change and the filter materials are not significantly affected by heat.

leeb hardness testing method|units for rockwell hardness test